How is air contamination prevented when inoculating loop – Ensuring the prevention of air contamination during inoculation procedures is crucial to maintain the sterility of cultures and prevent the introduction of unwanted microorganisms. This article explores the methods, techniques, and practices employed to minimize air contamination during the inoculation of loops, ensuring the accuracy and reliability of microbiological studies.

By adhering to strict protocols and employing effective environmental controls, researchers can effectively prevent air contamination, safeguarding the integrity of their experiments and contributing to the advancement of scientific knowledge.

Introduction: How Is Air Contamination Prevented When Inoculating Loop

Preventing air contamination during inoculation procedures is crucial to ensure the accuracy and reliability of microbiological experiments. Air contamination can introduce unwanted microorganisms into the culture medium, leading to false positives or incorrect results.

Methods for Preventing Air Contamination, How is air contamination prevented when inoculating loop

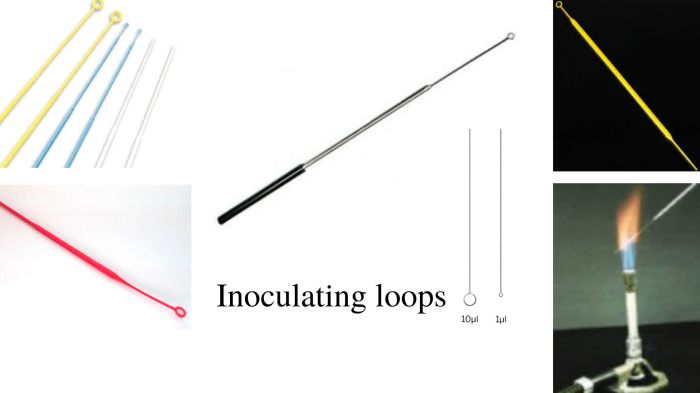

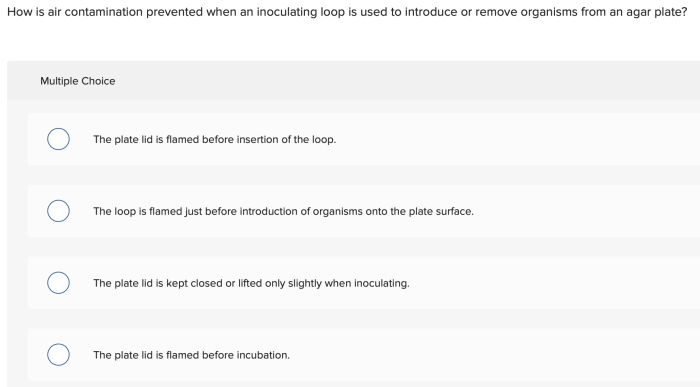

Sterile technique is essential for preventing air contamination. This includes proper handwashing, sterilization of equipment, and aseptic techniques.

- Sterilization of equipment involves using heat, chemicals, or radiation to kill microorganisms.

- Aseptic techniques minimize the risk of contamination by avoiding contact between the culture and the environment.

- Specific aseptic techniques include using sterile needles and syringes, transferring cultures in a laminar flow hood, and avoiding open flames.

Use of Sterile Equipment

Sterile needles, syringes, and other equipment are essential for preventing air contamination.

- Needles and syringes should be sterilized by autoclaving or dry heat sterilization.

- Other equipment, such as culture plates and tubes, can be sterilized by autoclaving, chemical sterilization, or UV radiation.

- Proper handling and storage of sterile equipment is crucial to maintain sterility.

Environmental Controls

Environmental controls play a vital role in preventing air contamination.

- Laminar flow hoods or biosafety cabinets create a sterile environment for inoculation procedures.

- These devices filter the air to remove microorganisms and direct the airflow away from the work area.

- Proper use and maintenance of these devices are essential to ensure their effectiveness.

Training and Education

Training and education are crucial for personnel involved in inoculation procedures.

- Proper training in aseptic techniques and environmental controls is essential to prevent air contamination.

- Ongoing education helps maintain proficiency in these techniques.

- Training programs should include both theoretical and practical components to ensure a comprehensive understanding of contamination prevention.

FAQ Explained

What is the significance of preventing air contamination during inoculation?

Preventing air contamination is essential to maintain the sterility of cultures and prevent the introduction of unwanted microorganisms that could compromise experimental results and lead to inaccurate conclusions.

What are the potential consequences of air contamination during inoculation?

Air contamination during inoculation can result in the introduction of foreign microorganisms into the culture, leading to false-positive results, skewed data, and compromised experimental outcomes.

How does sterile technique contribute to preventing air contamination?

Sterile technique involves the use of sterilized equipment and materials, as well as proper handwashing and disinfection procedures, to minimize the introduction of microorganisms from the environment.